In an era where energy storage solutions are desperately needed to support our transition to renewable power, most companies are betting on incremental improvements to lithium-ion batteries. But in a state-of-the-art facility in Utah, American company Torus is taking a radically different approach: storing electricity in massive steel wheels spinning at incredible speeds.

This isn’t just another startup with bold claims. In September 2025, Torus secured $200 million in funding from Magnetar Capital, one of the largest single investments in flywheel technology to date. The funding validates what might initially sound like an ancient solution for modern energy challenges, but represents a sophisticated fusion of mechanical engineering and grid-scale energy management.

The Critical Energy Storage Challenge Facing Modern Grids

Our electrical infrastructure operates on a fundamental principle that creates massive inefficiencies: electricity must be consumed the exact moment it’s generated. Unlike water, which can be stored in reservoirs, or natural gas, which can be stored in tanks, electrical energy has historically been impossible to store economically at scale.

This limitation becomes increasingly problematic as renewable energy sources like solar and wind make up larger portions of our electricity generation. Solar panels produce peak power during midday when demand is often lower, while wind turbines generate electricity when weather conditions are favorable, not necessarily when consumers need it most.

The mismatch between renewable energy generation and consumption patterns creates what grid operators call “duck curve” problems – sudden ramps in demand when the sun stops shining or wind stops blowing. Traditional power plants must constantly adjust output to maintain grid stability, a process that’s both expensive and technically challenging.

Current lithium-ion battery storage systems can help smooth these fluctuations, but they face several critical limitations. Most chemical batteries degrade rapidly under the constant charge-discharge cycles required for grid stabilization services. They typically need replacement every 3-5 years in commercial applications, making long-term economics challenging. Additionally, they respond relatively slowly to sudden grid demands and can be vulnerable to thermal runaway in extreme conditions.

This is precisely where Torus identified an opportunity to revolutionize energy storage using principles that predate the electrical grid by centuries.

The Science Behind Mechanical Energy Storage

Flywheel energy storage isn’t a new concept – engineers have been using spinning wheels to store kinetic energy since ancient times. What Torus has accomplished is scaling this mechanical approach to meet modern grid demands while achieving performance characteristics that complement rather than compete with chemical batteries.

The company’s Nova Spin system consists of massive steel rotors that can spin at extremely high speeds within vacuum chambers. When excess electricity is available from solar panels, wind turbines, or other sources, electric motors accelerate these wheels to store energy as rotational motion. The vacuum environment eliminates air resistance, while magnetic bearings reduce friction to nearly zero, allowing the wheels to maintain their rotation for extended periods.

When the electrical grid requires power, the spinning wheels function as generators, converting their stored kinetic energy back into electricity. This process can happen almost instantaneously – within milliseconds – making flywheel systems ideal for grid stabilization services that require rapid response times.

Torus’s innovation lies in combining these flywheel systems with traditional lithium-ion batteries in what they call a hybrid architecture. The Nova Pulse battery component handles longer-term energy storage, while the Nova Spin flywheel manages rapid power fluctuations and grid support services. This division of labor dramatically reduces stress on the chemical battery, potentially doubling or tripling its operational lifespan while providing grid operators with the fast response times they need for frequency regulation and voltage support.

The engineering precision required for these systems is remarkable. The steel rotors must be perfectly balanced to prevent destructive vibrations at high speeds. The vacuum chambers must maintain near-perfect seals to preserve the low-friction environment. The magnetic bearing systems must be robust enough to support massive rotating masses while precise enough to maintain perfect alignment over decades of operation.

Market Validation and Real-World Performance

The $200 million investment from Magnetar Capital represents more than just financial backing – it’s validation from sophisticated institutional investors who have thoroughly analyzed the technology’s commercial potential. Magnetar is known for data-driven investment strategies, and their commitment suggests confidence in both Torus’s technology and the broader market opportunity for mechanical energy storage.

This confidence appears well-founded based on Torus’s operational track record. The company reports having completed over 230 installations in 2025 alone, achieving 99.9% uptime across their deployed systems. This reliability metric is crucial for utility customers who need absolute certainty that grid support services will be available when required.

The commercial traction extends beyond individual installations. Torus has secured binding agreements with PacifiCorp for up to 500 MW of demand-response capacity, after an initial 70 MW contract was fully subscribed within six months. These utility-scale deployments demonstrate that flywheel technology has moved beyond niche applications to mainstream grid infrastructure.

Major commercial and industrial clients are also adopting the technology. Salt Lake City International Airport has implemented Torus systems for both power quality and backup power applications. Ash Grove Cement and other industrial facilities are using the systems for peak demand management and power factor correction. These real-world applications provide valuable operational data while building the track record that risk-averse utility customers require.

The recognition extends beyond commercial success. TIME magazine included Nova Spin in their “Best Inventions 2024” list, specifically highlighting the 25-year operational lifespan and the system’s potential to transform energy storage economics. This mainstream recognition helps legitimize flywheel technology for customers who might otherwise be skeptical of non-traditional storage approaches.

Global Flywheel Technology Development

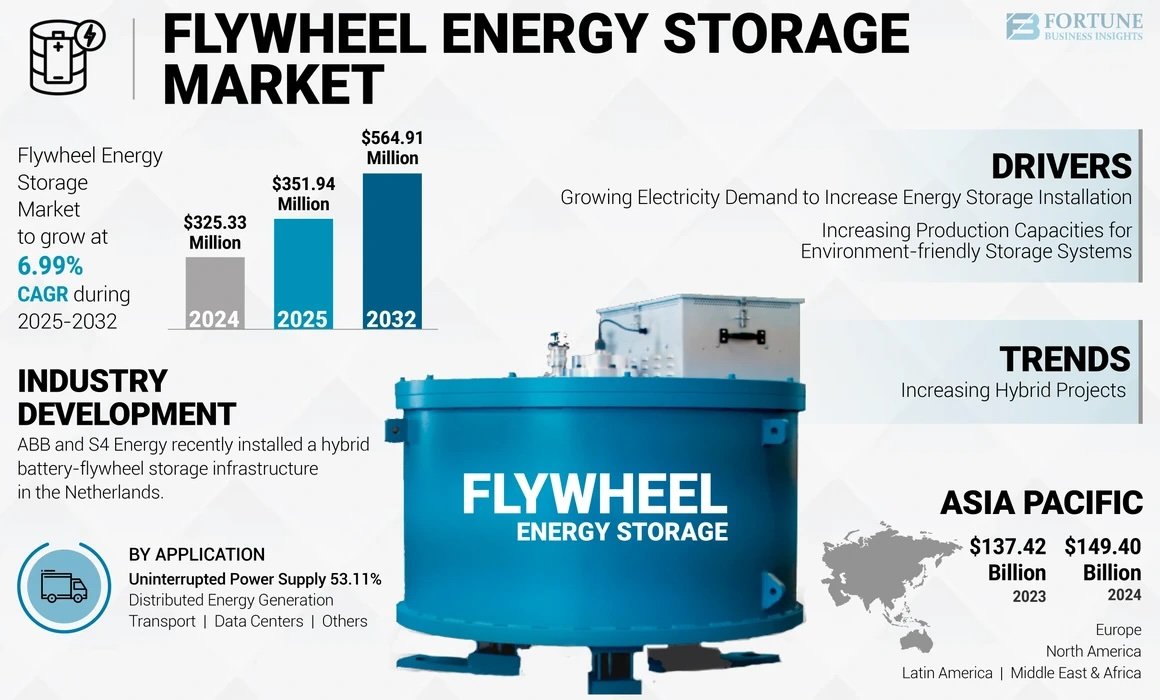

Torus isn’t operating in isolation – flywheel energy storage is experiencing renewed interest globally as grid operators seek alternatives to chemical batteries for specific applications. China connected a 30 MW flywheel project to their grid in 2024, representing the largest single flywheel installation announced to date.

Even more ambitious is China’s 200 MW hybrid flywheel-battery facility under construction in Shanxi Province. This 100.83 MWh system is designed specifically for frequency regulation and peak shaving services, validating the hybrid approach that Torus has pioneered.

The international development suggests that flywheel technology is transitioning from experimental status to commercial viability. CleanTechnica has noted that renewable-friendly storage solutions like flywheels are attracting increased investment as grid operators recognize the limitations of relying solely on chemical batteries for all storage applications.

Interestingly, flywheel applications are expanding beyond traditional grid services. POWER Magazine has documented how port operations are using flywheel systems to manage the massive power demands of cargo handling equipment, demonstrating the technology’s versatility across different industrial applications.

The Economics of 25-Year Energy Storage

Perhaps the most compelling aspect of Torus’s flywheel technology is its potential to fundamentally change energy storage economics through exceptional longevity. While lithium-ion batteries typically require replacement every 3-5 years in grid applications, mechanical flywheel systems are designed to operate for 25 years with minimal maintenance.

This durability stems from the fundamental nature of mechanical versus chemical energy storage. Chemical batteries degrade through repeated charge-discharge cycles as lithium ions move between electrodes, gradually reducing capacity and increasing internal resistance. Flywheel systems store energy as rotational motion, avoiding the chemical processes that limit battery lifespan.

The economic implications are significant. A flywheel system that operates for 25 years effectively replaces 5-8 battery systems over the same period. While the upfront capital cost may be higher, the total cost of ownership over the system’s lifetime can be substantially lower, especially when considering the labor and downtime costs associated with battery replacements.

This longevity also provides predictable revenue streams for energy storage investors. Grid services contracts typically span 10-20 years, and knowing that the physical infrastructure won’t require major replacements during the contract period makes project financing more attractive and potentially less expensive.

The maintenance requirements for flywheel systems are minimal compared to chemical batteries. The vacuum chambers and magnetic bearings require periodic inspection, but there are no chemical components to degrade or thermal management systems to maintain. This reduces both operational costs and the technical expertise required for system maintenance.

Advanced Applications and Grid Services

Modern electrical grids require numerous ancillary services beyond simple energy storage and discharge. Frequency regulation maintains the grid’s 60 Hz frequency as load and generation constantly fluctuate. Voltage support maintains proper voltage levels across transmission and distribution networks. Reserve services provide backup power when generators unexpectedly go offline.

Torus’s flywheel systems excel at these ancillary services because of their millisecond response times and high cycle life. Traditional generators take minutes to start up and reach full output, while chemical batteries may take seconds to respond to grid signals. Flywheel systems can inject or absorb power almost instantaneously, making them ideal for maintaining grid stability in real-time.

The systems are particularly valuable for data centers, which represent one of the fastest-growing sources of electricity demand. Data centers require uninterrupted power supplies and can experience dramatic load fluctuations as computing demands change. The hybrid flywheel-battery approach provides both instant response for sudden load changes and sustained backup power for extended outages.

Renewable energy integration presents another compelling application. Solar and wind power create grid instability due to their variable and sometimes unpredictable output. Flywheel storage can smooth these fluctuations while storing excess energy during periods of high renewable generation. The fast response times help grid operators maintain stability even as renewable penetration increases.

Industrial peak shaving represents a growing market opportunity. Manufacturing facilities often face demand charges based on their highest power consumption during billing periods. By storing energy during low-demand periods and discharging during peak consumption, facilities can significantly reduce their electricity costs. The 25-year lifespan makes the economics particularly attractive for industrial applications with stable long-term power needs.

Technology Limitations and Engineering Challenges

Despite their advantages, flywheel energy storage systems face inherent limitations that constrain their applications. Individual flywheel systems can only store energy for minutes to hours, not the days or weeks possible with chemical batteries or pumped hydro storage. This makes them unsuitable for seasonal energy storage or long-duration backup power applications.

The energy density of flywheel systems is also lower than modern lithium-ion batteries. Storing large amounts of energy requires proportionally large and heavy rotating masses, which can make flywheel systems impractical for space-constrained applications. The vacuum chambers and safety containment required for high-speed rotating systems also add to the physical footprint and infrastructure requirements.

Safety considerations are paramount with flywheel systems. A steel rotor spinning at high speeds contains enormous kinetic energy that must be safely contained in the event of mechanical failure. The containment systems must be robust enough to stop a disintegrating rotor without compromising the surrounding infrastructure. This requires sophisticated engineering and adds to system costs.

The precision manufacturing required for flywheel systems can also be challenging to scale. The rotating components must be perfectly balanced to prevent destructive vibrations, and the magnetic bearing systems require tight tolerances and sophisticated control systems. This manufacturing complexity can limit production scalability and increase costs compared to more standardized battery technologies.

Grid interconnection can present technical challenges as well. Flywheel systems must interface with electrical grids through power electronics that convert the variable frequency output of the rotating generators to fixed-frequency AC power. These power electronics must be highly reliable and efficient, adding complexity and potential failure points to the overall system.

The Connection to Battery Innovation Trends

The hybrid approach pioneered by Torus reflects broader trends in energy storage technology. Rather than seeking a single solution for all applications, the industry is increasingly recognizing that different storage technologies excel in different roles. CATL’s recent sodium battery developments demonstrate how even chemical battery technologies are specializing for specific applications like affordable electric vehicles.

Similarly, Mercedes’ partnership with Factorial Energy on solid-state batteries shows how premium applications are driving development of higher-performance but more expensive storage technologies. The flywheel-battery hybrid approach allows grid operators to optimize for both performance and cost by using each technology where it performs best.

The global competitive landscape in energy storage is intensifying, with China controlling 55% of the global battery market. Mechanical storage technologies like flywheels may offer Western companies an opportunity to compete in energy storage markets where they lack advantages in chemical battery manufacturing.

This technological diversification extends beyond terrestrial applications. Scotland’s Orbital O2 floating tidal turbine demonstrates how renewable energy generation is also becoming more specialized and geographically distributed, creating demand for equally diverse storage solutions.

Future Outlook and Scaling Challenges

Torus has announced ambitious expansion plans, targeting over 1 GW of quarterly capacity deployment within three years and developing a manufacturing facility they call “GigaOne.” Achieving this scale will require overcoming several significant challenges.

Supply chain development represents the first major hurdle. The precision steel components, magnetic bearings, and vacuum chamber systems required for flywheel storage are not commodity products with established supply chains. Torus will need to develop supplier relationships and potentially invest in specialized manufacturing capabilities to achieve their scaling targets.

Regulatory approval processes can also slow deployment, particularly for utility-scale installations. Grid interconnection studies, environmental reviews, and permitting processes can take months or years, potentially constraining the rapid deployment schedules that Torus has announced.

Market education remains important as well. Many utility engineers and grid operators have limited experience with flywheel technology, preferring the familiar characteristics of chemical batteries or traditional generators. Building confidence in mechanical storage will require continued demonstration of reliability and performance across diverse applications.

The competitive landscape is also evolving rapidly. Lithium-ion battery costs continue declining, and new battery chemistries like sodium-ion and solid-state technologies may address some of the current limitations of chemical storage. Torus will need to continuously improve their technology and reduce costs to maintain competitive advantages.

Despite these challenges, the fundamental value proposition of 25-year mechanical storage systems appears compelling for many grid applications. As renewable energy continues expanding and grid stability becomes increasingly critical, the combination of fast response times and exceptional longevity positions flywheel technology as a valuable complement to chemical batteries.

Investment Implications and Market Positioning

The $200 million investment in Torus reflects broader institutional recognition that energy storage markets will likely support multiple technologies rather than a single dominant solution. Grid operators are increasingly sophisticated about matching storage technologies to specific applications, creating market opportunities for specialized solutions.

The flywheel market positioning also benefits from growing concerns about supply chain security and raw material availability for lithium-ion batteries. Mechanical storage systems use common materials like steel and avoid dependence on lithium, cobalt, and other materials with constrained supply chains or geopolitical risks.

For investors, flywheel energy storage offers exposure to grid modernization trends while potentially avoiding some of the competitive pressures facing chemical battery manufacturers. The 25-year system lifetime also creates more predictable revenue streams compared to technologies that require frequent equipment replacements.

Conclusion: Mechanical Storage in an Electric Future

Torus’s success in attracting substantial investment and securing utility-scale contracts demonstrates that mechanical energy storage has evolved far beyond academic curiosity to become a practical grid technology. The company’s hybrid approach cleverly combines the fast response times and longevity of flywheel systems with the energy density and duration capabilities of chemical batteries.

The technology’s 25-year operational lifespan addresses one of the most significant economic challenges facing energy storage deployment – the recurring costs and operational disruption of equipment replacement. For grid applications that prioritize reliability and predictable economics over maximum energy density, mechanical storage offers compelling advantages.

As our electrical grid continues evolving to accommodate higher levels of renewable generation and increasingly complex demand patterns, energy storage diversity will likely prove more valuable than any single technology solution. Torus’s spinning wheels represent not just an alternative to batteries, but a demonstration that innovation in energy storage can come from reimagining ancient technologies with modern engineering precision.

The success of this mechanical approach may inspire other companies to explore equally unconventional storage solutions, potentially accelerating the development of diverse technologies needed for a fully renewable electrical grid. In an industry often focused on incremental improvements to established technologies, sometimes the most revolutionary advancement comes from spinning wheels that have been storing energy for millennia.

Recommended Tools and Resources

For those interested in learning more about energy storage technologies and staying updated on breakthrough innovations like Torus’s flywheel systems, we recommend the following professional tools:

Video Creation and Education:

- Fliki – Create professional video content about energy technologies with AI-powered tools (20% OFF)

- Pictory – Transform energy research into engaging video content (20% OFF with Code: CuriosityAI)

- Synthesia – Develop educational videos about complex technologies using AI avatars

Professional Audio and Presentations:

- ElevenLabs – Generate realistic voiceovers for technical presentations and educational content

- Murf AI – Professional AI voiceover solutions for business presentations

Research and Analytics:

- vidIQ – Optimize energy content for YouTube discovery and audience growth

- AdCreative.ai – Design professional marketing materials for clean technology businesses

Communication and Networking:

- Beehiiv – Build newsletters focused on energy innovation and technology trends

Professional Development:

- Coursera – Access specialized courses in renewable energy, grid technology, and energy storage systems

Privacy and Security:

- Surfshark VPN – Secure your energy research and business communications

- NordVPN – Professional-grade security for energy industry professionals

These tools can help professionals in the energy sector create content, conduct research, and communicate effectively about breakthrough technologies like flywheel energy storage.