Led by Professor Leif Asp, the Chalmers team has achieved remarkable progress in developing carbon fiber composite batteries that store electrical energy while providing mechanical support equivalent to aluminum structures. This breakthrough could fundamentally transform how we design everything from smartphones to electric vehicles, making devices lighter, more efficient, and longer-lasting.

Revolutionary Breakthrough: The Science Behind Structural Battery

Composites

Structural battery composites represent a revolutionary approach to energy storage that integrates electrochemical functionality directly into load-bearing materials. Unlike conventional batteries housed in separate containers, these innovative composites serve dual purposes: storing electrical energy and providing structural support to the device or vehicle they power.

Understanding the Core Technology

The fundamental innovation lies in using carbon fiber as both an electrode material and a structural component. Traditional batteries require separate housing that adds weight without contributing to the device’s structural integrity. Structural battery composites eliminate this redundancy by making the battery itself part of the framework.

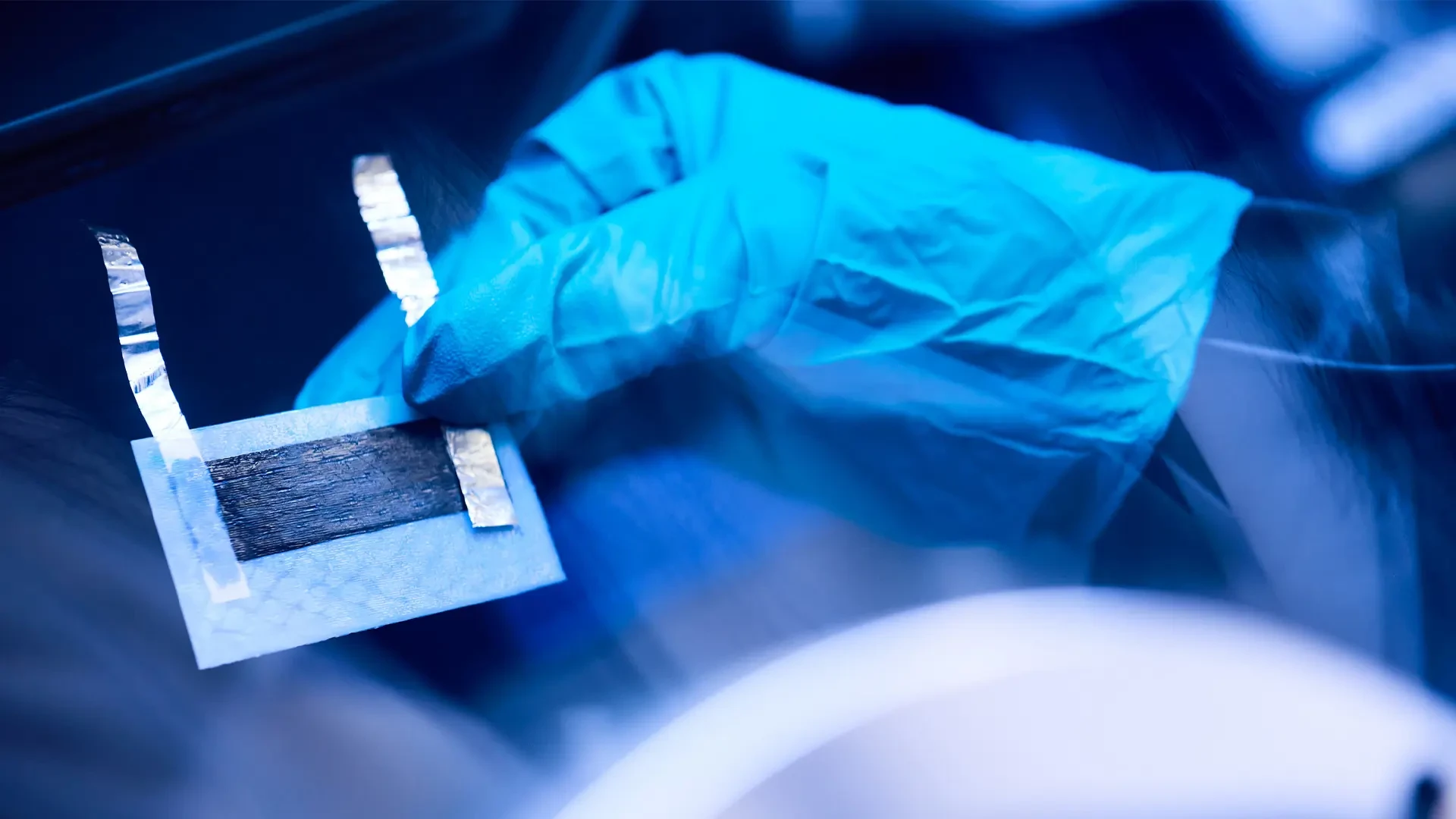

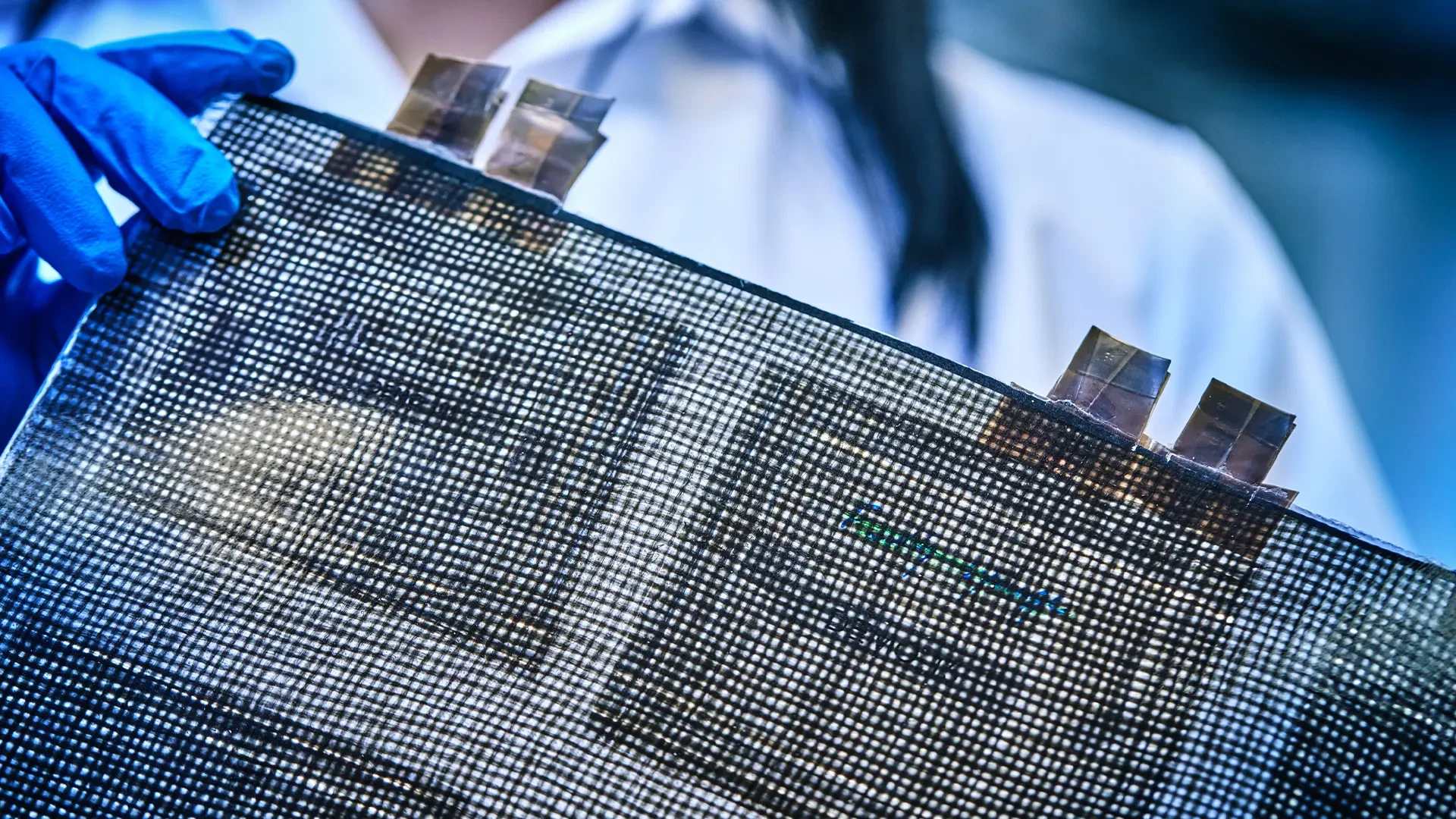

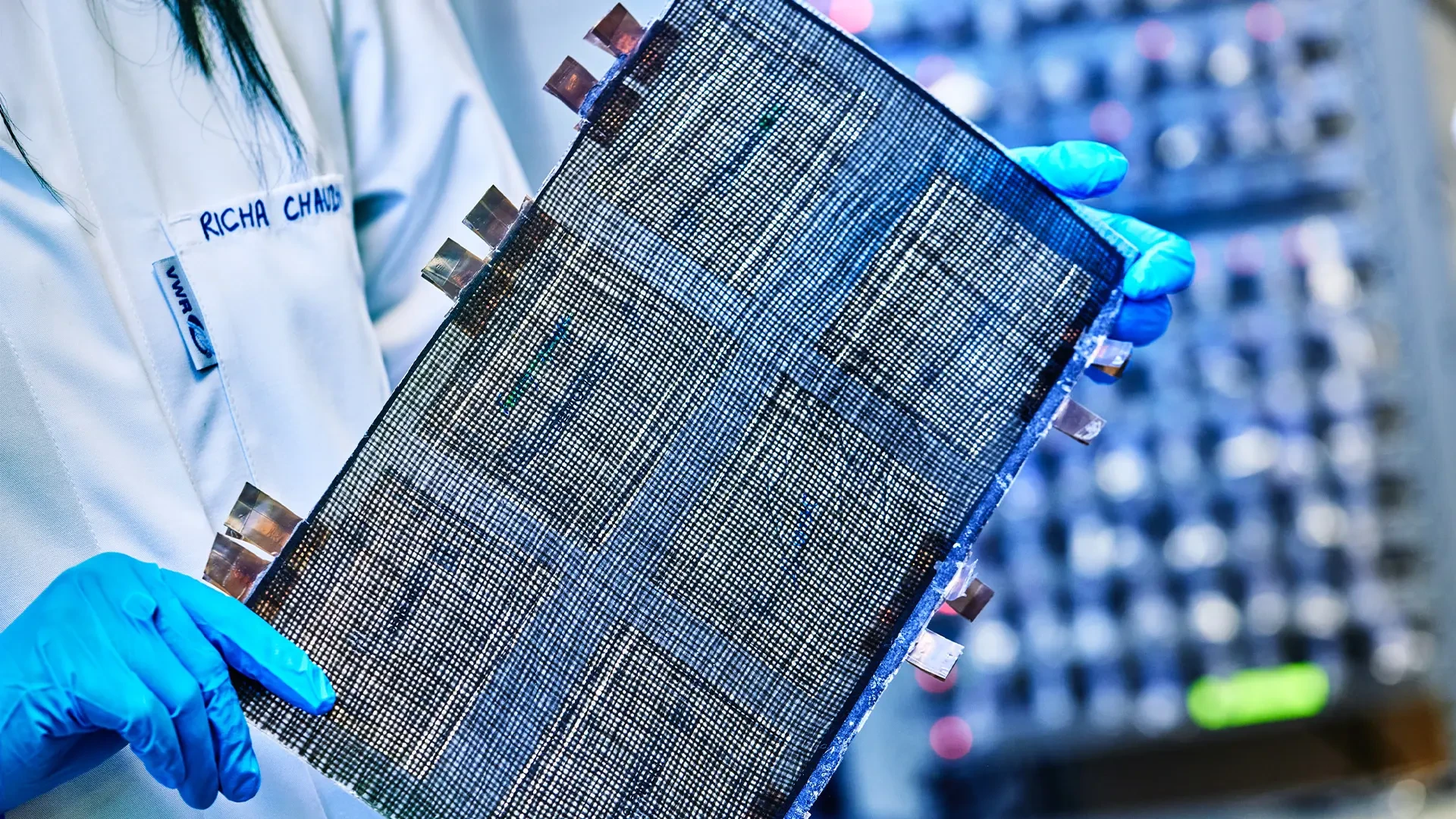

Professor Leif Asp’s team at Chalmers University has pioneered a design where carbon fiber serves as the negative electrode, while a lithium iron phosphate (LFP) coated carbon fiber functions as the positive electrode. A cellulose-based separator approximately 30 micrometers thin enables ionic transport while maintaining structural rigidity.

The manufacturing process involves vacuum-assisted infusion of a biphasic solid-liquid electrolyte system, which cures into a rigid composite structure. This technique, adapted from aerospace composite manufacturing, ensures both electrical functionality and mechanical strength are optimized simultaneously.

Remarkable Performance Evolution

The progression of Chalmers’ structural battery technology showcases rapid advancement in both energy storage and mechanical properties. In 2021, their initial prototypes achieved approximately 24 watt-hours per kilogram with an elastic modulus of 25 gigapascals. By 2024, significant improvements brought energy density to 30 Wh/kg while dramatically increasing stiffness to 76 GPa.

Recent 2025 developments have pushed performance even further, with advanced prototypes exceeding 60 Wh/kg energy density and achieving elastic modulus values surpassing 100 GPa. This represents double the multifunctional performance compared to previous generations, establishing these composites as genuinely viable alternatives to traditional battery and structural material combinations.

Moreover, the latest prototypes demonstrate exceptional cycle stability, maintaining approximately 100% coulombic efficiency over 1000 charge-discharge cycles. This longevity, combined with improved energy density, positions structural battery composites as commercially viable solutions for various applications.

Engineering Marvel: Dual-Function Design

The engineering achievement of structural battery composites lies in optimizing two seemingly contradictory requirements simultaneously. Energy storage demands materials with high ionic conductivity and electrochemical activity, while structural applications require mechanical strength, stiffness, and durability under load.

Carbon fiber emerges as the ideal solution due to its unique combination of properties. As an electrode material, carbon fiber provides excellent electrical conductivity and can store lithium ions effectively. Structurally, carbon fiber offers exceptional strength-to-weight ratios, making it ideal for aerospace and automotive applications.

The electrolyte matrix plays a crucial role in this dual functionality. Advanced polymer electrolytes developed by the Chalmers team provide ionic transport while contributing to the composite’s mechanical properties. This integrated approach ensures that neither function compromises the other, achieving true multifunctional performance.

Transformative Applications Across Industries

Revolutionizing Consumer Electronics

The most immediate impact of structural battery composites will likely appear in consumer electronics, where weight and thickness constraints drive innovation. Professor Leif Asp envisions smartphones as thin as credit cards while maintaining current battery life, fundamentally changing mobile device design paradigms.

Current smartphone batteries occupy significant internal volume and require protective housing that adds weight and thickness. Structural battery composites could integrate directly into the device frame, eliminating separate battery compartments entirely. This integration would enable designers to create devices with unprecedented form factors while improving durability.

Laptops represent another compelling application, with potential weight reductions of approximately 50% compared to current models. The structural battery could replace traditional internal frames while providing power, creating ultralight portable computers with extended operational time. This transformation would particularly benefit professional users who demand both portability and performance.

Furthermore, wearable devices could benefit enormously from structural battery integration. Smartwatches, fitness trackers, and augmented reality glasses could achieve longer battery life while reducing bulk, improving user comfort and adoption rates significantly.

For those interested in creating educational content about these emerging technologies, platforms like Fliki enable the creation of professional videos that can effectively explain complex battery concepts to wider audiences.

Electric Vehicle Revolution

The automotive industry shows intense interest in structural battery composites due to their potential to address electric vehicle range anxiety while reducing manufacturing complexity. Current EV batteries constitute significant portions of vehicle weight without contributing to structural integrity, representing an engineering inefficiency that structural composites could eliminate.

Integration of structural batteries into EV chassis panels could reduce overall vehicle weight by 20-30%, directly translating to approximately 70% increased driving range without adding battery capacity. This improvement stems from the fundamental physics of vehicle dynamics, where weight reduction provides compounding benefits for energy efficiency.

Moreover, structural battery integration could simplify EV manufacturing by reducing part count and assembly complexity. Traditional EVs require separate battery packs, mounting systems, and structural frames. Structural composites could consolidate these functions, potentially reducing production costs while improving crash safety through better energy distribution.

The technology also enables new vehicle architectures impossible with conventional batteries. Designers could distribute energy storage throughout the vehicle structure, optimizing weight distribution and potentially improving handling characteristics. This flexibility could lead to innovative vehicle designs that blur the boundaries between energy storage and structural elements.

While companies like CATL and BYD focus on advancing traditional lithium-ion technology, structural batteries represent a completely different approach to solving EV range and weight challenges.

Aerospace and Industrial Applications

Aerospace applications represent perhaps the most demanding use case for structural battery composites, where weight savings directly impact fuel efficiency and payload capacity. Aircraft manufacturers constantly seek weight reduction opportunities, making structural batteries particularly attractive for aviation applications.

Commercial aircraft could integrate structural batteries into non-critical structural components, providing auxiliary power for cabin systems while reducing overall aircraft weight. Military applications could benefit even more dramatically, with unmanned aerial vehicles (UAVs) achieving extended flight times through structural battery integration in wing structures or fuselage components.

Industrial applications include wind turbine blades embedded with structural batteries to power monitoring systems, marine vessels with hull-integrated energy storage, and construction equipment with structural power sources. These applications leverage the technology’s dual functionality to improve system efficiency while reducing maintenance requirements.

Additionally, space applications present unique opportunities where every gram matters. Satellites and spacecraft could benefit from structural batteries that provide both power and structural support, enabling more efficient designs for long-duration missions.

Market Dynamics and Economic Impact

Rapid Market Growth Projections

The structural battery technology market demonstrates strong growth potential, with current valuations reaching $1.598 billion in 2025 and projected compound annual growth rates of approximately 16% through 2033. This expansion reflects increasing industry recognition of the technology’s transformative potential across multiple sectors.

Market drivers include growing demand for lightweight electric vehicles, increasing smartphone performance requirements, and aerospace industry weight reduction initiatives. Additionally, sustainability concerns drive interest in technologies that improve energy efficiency through structural optimization rather than simply adding more battery capacity.

The Swedish innovation cluster around Chalmers University positions Scandinavia as a potential leader in structural battery commercialization. Companies like Sinonus AB, a Chalmers spin-off, aim to bridge the gap between laboratory research and industrial production, potentially creating significant economic value for the region.

Investment flows into structural battery research and development continue accelerating, with venture capital firms and automotive manufacturers showing particular interest. For professionals interested in understanding the broader implications of battery technology evolution, specialized learning platforms offer comprehensive courses on energy storage and materials science.

Manufacturing Challenges and Scalability

Despite promising performance characteristics, structural battery composites face significant manufacturing challenges that must be addressed for widespread adoption. Current production methods, adapted from aerospace composite manufacturing, are not easily scalable to automotive or consumer electronics volumes.

Vacuum-assisted infusion processes require precise control of temperature, pressure, and curing cycles, making automation and quality control more complex than traditional battery manufacturing. Additionally, carbon fiber production remains energy-intensive and expensive compared to conventional battery materials.

However, economies of scale and manufacturing innovation could address these challenges. As production volumes increase, carbon fiber costs should decrease while process automation improves quality consistency. The automotive industry’s experience with carbon fiber components suggests that large-scale production is achievable with sufficient investment and development time.

Quality control represents another critical challenge, as structural batteries must meet both electrochemical and mechanical performance standards simultaneously. This dual requirement necessitates new testing protocols and certification processes that don’t currently exist in either the battery or structural materials industries.

Technical Challenges and Engineering Solutions

Performance Optimization Strategies

While structural battery composites show remarkable progress, current energy density levels still lag behind conventional lithium-ion batteries. The 60+ Wh/kg achieved by latest Chalmers prototypes represents approximately 60% of conventional LFP battery energy density, creating trade-offs that must be carefully evaluated for each application.

To understand how structural batteries fit into the broader landscape of battery technology evolution, it’s important to consider them as complementary rather than replacement technologies for specific use cases.

Research continues focusing on improving both energy density and mechanical properties simultaneously. Advanced carbon fiber treatments, optimized electrolyte formulations, and novel separator designs all contribute to performance enhancement. The goal is achieving energy densities approaching conventional batteries while maintaining superior mechanical properties.

Power density optimization represents another critical area, as structural applications often require rapid energy delivery for acceleration or peak demand situations. Current prototypes achieve approximately 46 watts per kilogram on a cell mass basis, which may be sufficient for many applications but could limit high-performance uses.

Cycle life improvement efforts focus on understanding degradation mechanisms specific to structural composites. Mechanical stress cycling combined with electrochemical cycling creates complex degradation patterns that require specialized analysis and mitigation strategies not necessary for conventional batteries.

Safety and Reliability Considerations

Structural battery composites introduce unique safety challenges that combine electrochemical hazards with structural failure risks. Traditional battery safety focuses primarily on thermal runaway prevention and electrical safety, while structural applications add mechanical failure modes that could compromise device or vehicle safety.

Crash safety represents a particular concern for automotive applications, where structural batteries must continue functioning safely even after significant mechanical damage. Research into fail-safe designs and protective systems ensures that structural battery failures don’t cascade into larger safety problems.

Environmental resilience testing examines how structural batteries perform under temperature cycling, humidity exposure, and mechanical fatigue conditions typical of real-world applications. These conditions can affect both electrochemical performance and structural integrity, requiring comprehensive testing protocols.

Quality assurance systems must verify both electrical and mechanical properties throughout the manufacturing process. This dual verification requirement increases complexity and cost compared to traditional battery or structural component manufacturing, but is essential for safety-critical applications.

Integration and Design Challenges

Integrating structural batteries into existing design paradigms requires significant engineering innovation across multiple disciplines. Electrical engineers must work closely with mechanical engineers to optimize both functions simultaneously, a collaboration that doesn’t traditionally exist in product development.

Thermal management becomes more complex when batteries are integrated into structural components, as heat dissipation pathways change dramatically. Traditional battery cooling systems may not be applicable to structural configurations, requiring novel thermal management approaches.

Electrical connections and service access represent practical challenges for structural battery implementations. Unlike replaceable conventional batteries, structural batteries become integral to device architecture, complicating repair and maintenance procedures. This permanence requires exceptional reliability and longevity.

Design flexibility decreases when batteries become structural elements, as changes to battery specifications affect structural properties and vice versa. This interdependence requires more sophisticated design optimization tools and longer development cycles compared to conventional approaches.

Competitive Landscape and Innovation Ecosystem

Academic Research Leadership

Chalmers University of Technology has established clear leadership in structural battery research through consistent innovation and high-impact publications. Their collaboration with KTH Royal Institute of Technology strengthens Sweden’s position as the global center for structural battery development.

International research efforts include work at Imperial College London on multifunctional composites, though their focus remains more theoretical compared to Chalmers’ practical implementations. Other universities worldwide are beginning structural battery research programs, but none have achieved the performance levels demonstrated by the Swedish teams.

The academic research community benefits from strong collaboration between materials scientists, electrical engineers, and mechanical engineers. This interdisciplinary approach proves essential for addressing the complex challenges inherent in multifunctional material development.

Publication in prestigious journals like Advanced Materials validates the scientific rigor of structural battery research while disseminating knowledge to the broader research community. These publications also establish intellectual property foundations for future commercialization efforts.

Researchers and educators looking to create compelling visual explanations of these complex technologies often utilize professional video editing tools to transform research data into accessible educational content.

Commercial Development Initiatives

Sinonus AB represents the primary commercial vehicle for Chalmers’ structural battery technology, though the company maintains a relatively low public profile while developing manufacturing capabilities. Their approach focuses on technology transfer and industrial partnerships rather than direct consumer product development.

Traditional battery manufacturers have shown limited interest in structural battery technology, viewing it as a niche application rather than a mainstream opportunity. This perspective may change as performance improvements continue and market demand becomes clearer.

Automotive manufacturers express significant interest in structural battery potential, with several major companies reportedly exploring partnerships or licensing arrangements. However, the automotive industry’s long development cycles mean commercial implementation may still be several years away even with current technology.

The aerospace industry shows perhaps the strongest commercial interest due to weight sensitivity and willingness to adopt advanced materials. Several aerospace companies have initiated research programs or partnerships exploring structural battery applications for both commercial and military aircraft.

Investment and Funding Landscape

Venture capital investment in structural battery technology remains limited but growing, with most funding directed toward university research rather than commercial development. The Wallenberg Initiative Materials Science for Sustainability provides significant funding for Chalmers research, enabling continued innovation.

Government funding through European Union research programs and Swedish national initiatives supports basic research while encouraging commercial development. These funding sources prove crucial for bridging the gap between laboratory research and industrial implementation.

Corporate investment from automotive and aerospace companies increasingly supplements academic funding, providing both financial resources and practical application guidance. These partnerships help ensure research directions align with commercial requirements and market needs.

Patent landscapes around structural battery technology remain relatively open, with most intellectual property held by academic institutions rather than commercial entities. This situation provides opportunities for new entrants while potentially limiting long-term competitive advantages for current leaders.

Future Development Roadmap and Commercial Timeline

Short-Term Developments (2025-2027)

The immediate future of structural battery composites focuses on refining energy density and mechanical properties while developing manufacturing processes suitable for pilot production. Chalmers researchers target energy densities exceeding 60 Wh/kg while maintaining elastic modulus values above 100 GPa.

Consumer electronics applications will likely see the first commercial implementations, as these markets accept higher costs for performance advantages and have shorter development cycles compared to automotive applications. Smartphone and laptop prototypes incorporating structural batteries may appear within this timeframe.

Manufacturing process development concentrates on adapting aerospace composite techniques for higher-volume production. Automation improvements and quality control systems enable consistent production of structural battery components while reducing costs and improving reliability.

Safety certification and testing protocol development proceeds in parallel with technology advancement, ensuring that commercial products meet appropriate safety standards for their intended applications. This work establishes foundations for regulatory approval in various markets.

Medium-Term Projections (2027-2030)

Automotive applications begin transitioning from research to development programs as structural battery performance reaches commercially viable levels. Pilot programs with automotive manufacturers test structural battery integration in non-critical components before moving to primary structural elements.

Manufacturing scalability improvements enable production volumes suitable for specialty applications while costs decrease through economies of scale and process optimization. Industrial production facilities may begin operation during this period, moving beyond laboratory-scale production.

Energy density targets approach conventional battery levels while mechanical properties exceed traditional structural materials, creating compelling value propositions for various applications. This performance crossover point triggers broader market adoption across multiple industries.

Regulatory frameworks and safety standards specific to structural batteries emerge as commercial applications expand. These standards provide clarity for manufacturers while ensuring appropriate safety levels for consumers and industrial users.

Long-Term Vision (2030-2035)

Mass market adoption of structural batteries in electric vehicles becomes realistic as performance, cost, and manufacturing capabilities reach automotive industry requirements. Vehicle designs incorporating structural batteries may fundamentally change automotive architecture and capabilities.

Aerospace applications mature from experimental to operational status, with commercial aircraft potentially incorporating structural batteries in auxiliary systems before advancing to primary power applications. Military and space applications may lead adoption due to performance advantages outweighing cost considerations.

Energy density and mechanical property improvements continue through materials innovation and manufacturing refinement. Advanced carbon fiber treatments, novel electrolyte systems, and optimized composite structures push performance boundaries further.

Market expansion beyond current application areas may emerge as technology capabilities improve and costs decrease. Construction, marine, and industrial equipment markets could adopt structural batteries for applications not currently envisioned.

For industry professionals tracking these developments, staying informed through specialized newsletters focusing on battery technology advances can provide valuable insights into market trends and technological breakthroughs.

Understanding the historical context of battery technology evolution helps appreciate the significance of structural battery innovations in the broader energy storage landscape.

Environmental Impact and Sustainability Considerations

Lifecycle Assessment Analysis

Recent lifecycle assessment studies of structural battery composites reveal complex environmental trade-offs that must be carefully evaluated against conventional alternatives. While carbon fiber production requires significant energy input, the use-phase benefits of weight reduction in transportation applications can offset manufacturing impacts over time.

Manufacturing emissions for structural batteries are currently higher than conventional batteries due to carbon fiber production energy requirements. However, research into bio-based carbon fiber precursors and renewable energy-powered manufacturing could significantly reduce these impacts in future production systems.

The multifunctional nature of structural batteries eliminates the need for separate structural materials, reducing overall material consumption and associated environmental impacts. This material efficiency becomes more significant as production scales increase and manufacturing processes optimize.

End-of-life considerations for structural batteries require new recycling approaches that recover both carbon fiber and battery materials effectively. Current recycling infrastructure focuses on either batteries or composite materials separately, necessitating integrated recycling technologies for structural battery composites.

Resource Efficiency Advantages

Structural battery composites offer potential resource efficiency advantages through material consolidation and improved energy utilization. By eliminating redundant materials and optimizing device weights, these technologies could reduce overall material consumption in transportation and electronics applications.

The longevity potential of structural batteries, demonstrated through 1000+ cycle testing, suggests extended product lifespans compared to conventional battery systems. This durability could reduce replacement frequency and associated resource consumption over product lifecycles.

Regional resource security benefits may emerge as structural battery technology reduces dependence on traditional battery materials while leveraging existing carbon fiber and composite material supply chains. This diversification could improve supply chain resilience and reduce geopolitical risks.

Manufacturing process efficiency improvements through automation and scale optimization should reduce energy consumption per unit while improving quality consistency. These improvements contribute to overall sustainability by reducing waste and improving resource utilization efficiency.

Global Innovation Competition and Strategic Implications

International Technology Leadership

Sweden’s leadership in structural battery technology through Chalmers University research creates significant strategic advantages for the Nordic region. This technological leadership could translate into economic benefits through licensing, manufacturing, and export opportunities as markets develop.

China’s rapid advancement in conventional battery technology creates competitive pressure for alternative approaches like structural batteries. European and American companies may view structural batteries as differentiation opportunities against Chinese battery manufacturing dominance.

The United States shows increasing interest in structural battery research through defense and aerospace applications, potentially creating competition with European research leadership. American aerospace companies have initiated research programs that could challenge Swedish technological advantages.

Technical presentations explaining these competitive dynamics often benefit from AI-powered presentation tools that can create professional explanations of complex battery technologies for various audiences.

Asian technology companies, particularly from South Korea and Japan, may enter structural battery research as markets develop and commercial viability becomes clearer. These companies possess strong materials science capabilities and manufacturing expertise relevant to structural battery production.

Economic Development Opportunities

Regional economic development around structural battery technology could create significant value through high-technology manufacturing, research and development employment, and export revenues. Sweden’s early leadership position provides advantages for capturing these economic benefits.

Supply chain development for structural battery materials creates opportunities for existing composite and battery material suppliers to expand into new markets. This expansion could strengthen industrial ecosystems while reducing dependence on traditional supply chains.

Education and workforce development programs focused on structural battery technology could create competitive advantages through skilled labor availability. Universities and technical schools may develop specialized programs to support industry needs.

International collaboration opportunities through research partnerships, technology transfer agreements, and joint ventures could accelerate development while spreading economic benefits across participating regions and companies.

Researchers and industry professionals accessing international databases and research repositories often utilize secure network connections to ensure reliable access to global research resources and collaborative platforms.

Investment Implications and Market Opportunities

Technology Investment Strategies

Investors interested in structural battery technology face choices between supporting academic research, early-stage commercial development, or applications in specific market segments. Each approach offers different risk-return profiles and timeline considerations.

University spin-offs like Sinonus AB represent direct investment opportunities in structural battery commercialization, though these companies remain in early development stages with uncertain commercial timelines and significant technical risks.

Established companies exploring structural battery applications offer more stable investment opportunities with shorter commercialization timelines, though potential returns may be limited by competitive pressures and integration challenges within existing business models.

Portfolio approaches combining multiple structural battery investments across the value chain may provide better risk-adjusted returns while supporting overall technology development. These strategies hedge against specific company or application risks while maintaining exposure to technology upside.

Market Entry Considerations

Companies considering structural battery market entry must evaluate their existing capabilities against technology requirements and competitive landscapes. Materials science expertise, composite manufacturing experience, and battery technology knowledge all provide relevant advantages.

Licensing arrangements with academic institutions like Chalmers University offer lower-risk entry strategies for companies lacking internal research capabilities. These arrangements provide access to proven technology while allowing focus on manufacturing and commercialization challenges.

Partnership strategies with automotive, aerospace, or electronics companies provide market access and application expertise while sharing development costs and risks. These collaborations often prove essential for successful commercialization of advanced materials technologies.

Timing considerations for market entry must balance first-mover advantages against technology maturity and market readiness. Early entry provides competitive advantages but requires greater investment in technology development and market creation activities.

Conclusion: The Future of Integrated Energy Storage

Structural battery composites represent a fundamental shift in how we conceive energy storage and structural design. The breakthrough achievements by Professor Leif Asp’s team at Chalmers University demonstrate that the integration of energy storage and structural functionality is not only possible but commercially viable.

The progression from 24 Wh/kg in 2021 to over 60 Wh/kg in 2025, combined with mechanical properties exceeding 100 GPa, validates the potential for structural batteries to transform multiple industries. From credit card-thin smartphones to electric vehicles with 70% longer range, these innovations promise to reshape our technological landscape.

Sweden’s leadership in this field, supported by institutions like Chalmers University and companies like Sinonus AB, positions the Nordic region at the forefront of a potentially transformative technology. As commercial applications emerge over the next decade, structural battery composites may prove as revolutionary as the introduction of lithium-ion batteries themselves.

The challenges ahead are significant, encompassing manufacturing scalability, safety certification, and cost reduction. However, the fundamental scientific breakthroughs have been achieved, and the path to commercialization is increasingly clear. For industries seeking weight reduction, energy efficiency, and design flexibility, structural battery composites offer unprecedented opportunities.

As we look toward a future of electric transportation, portable electronics, and sustainable technology, structural battery composites provide a compelling vision of integrated, efficient, and powerful energy storage solutions. The Swedish scientists who pioneered this technology have opened a new chapter in materials science, one that promises to reshape how we build and power the devices and vehicles of tomorrow.

For a quick visual explanation of this breakthrough technology, watch our comprehensive breakdown of structural battery composites and their revolutionary applications.